Out-of-stock is very broad and is defined as happening if the customer when they come into a shop and cannot get the stock, they came to get.

I was reading a new study of the retail industry of how much is currently being lost by these stock-outs it makes quite shocking reading. According to this IHL’s research here out-of-stocks losses total £419.9bn billion in lost revenue annually for retailers and the leading causes are:

1) The stock is not in the shop (£157.7bn)

2) The customer could not find anyone to help them ( £80bn)

3) Staff could not find stock (£45.1bn)

4) Price/offer did not match advertising (£49.1bn)

5) For everything else the loss was £87.1bn

Now taking out number (5) because we have no details and number (4) is a supplier issue which the retailer cannot do anything about which should not happen but does all too often. A typical reason for (4) is that a supplier spends a great deal of money on advertising, and the retailer does not know about it in time and/or does know but does not get the correct stock.

We can say that (1) not having sufficient stock is only about half of the problem and its either a shop problem because they have not ordered enough for various reasons or a supplier issue as they have not sent enough stock. The other half of the problem (2) and (3) is probably the shop layout and/or staff knowledge and training.

Now in my experience its not so much shop layout, which is logical and fine but that over time as stock gets moved around people do not know or cannot figure out where the stock is hiding.

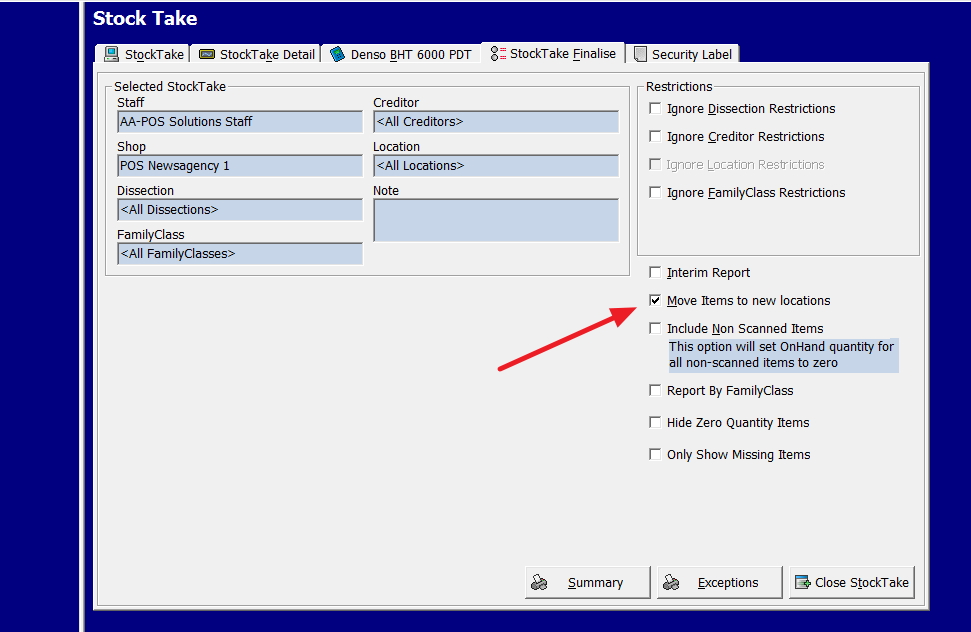

As such most of this can be solved if people used the stock location. Then all they need do is call up the stock item and see its location. This location can be added quickly to any stock item or added in bulk when doing a stocktake by telling the point-of-sale system to update the location, click on image below for more details.

By this simple procedure, the part we can solve of the out-of-stock problem is solved.