Most of your suppliers have large numbers of items on the catalogue. Even many small clients of ours would be selling actively over a year, selling over 43,000 lines. Your point of sale (POS) software can quickly give you a list of your inventory management. Smaller retailers sell less than large retailers but sell the same goods. That is a lot of work if you order once a week to handle it. Just calculate how much it costs you now to order stock.

Those who do not computerise it tend to do much of the ordering on gut feel and memory.

However, getting it right is critical to retail business success as we need to get the shoppers what they want and when they want it. This is particularly difficult if you deal with products with high decay, e.g. popular magazines, fresh food, etc., because then we have the problem of availability vs waste.

Inventory management is one of the most critical operations in retail. Ensuring adequate stock levels to meet customer demand takes careful planning and excellent forecasting skills. For most retailers, the replenishment process involves a lot of manual work, guesswork and frustration. But our POS Software offers a better way – retailers can revolutionise inventory management by automating replenishment.

The Challenges of Manual Replenishment

Traditionally, reordering stock is an entirely manual process for retailers. Staff pore over existing stock and review the massive catalogues from various suppliers to select items and quantities to purchase each week. This tedious approach to Retail inventory is problematic for several reasons:

Guessing Order Quantities

Without scientific forecasting, employees guess at order amounts based on intuition and memory. It’s virtually impossible to predict demand across an extensive product range this way accurately.

Time-Consuming

Manually calculating and entering purchase orders can take days of staff time every week. As the business grows, more labour hours get eaten up by this low-value activity.

Risk of Stockouts

Guessing order quantities often leads to stockouts when demand exceeds forecasts. Out-of-stocks result in missed revenue and poor customer experiences.

Excess Inventory

Just as dangerous, overestimating demand frequently causes overstocking. Excess inventory leads to higher carrying costs and waste.

Unbalanced Supply Chain

With no real-time visibility or coordination, discrepancies between inventory levels and supplier ordering accumulate over time. This strains the supply chain.

Imprecise Tracking

Lacking any automated analysis, inventory tracking relies on employees manually monitoring and recording stock counts. This is prone to error over a large catalogue.

Automated Replenishment

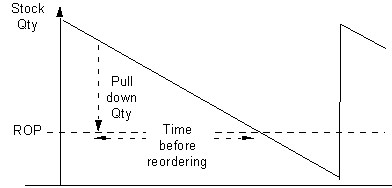

It looks at your sales history, forecasts current demand using Demand forecasting, and creates the ideal stock quantity you require now.

If you order frequently, the amount of stock you need until the next reorder is less. It then compares this figure to the actual stock-on-hand figure you have, adds some safety stock, considers the ordering requirement of each supplier, and prints or issues a stock order with almost no work.

This reduces your holding costs, as you are not holding much stock.

You will save a lot of time, and your shop will undoubtedly do a better job of it.

Our automated inventory management platforms provide a sophisticated solution to these challenges. By using smart forecasting algorithms and inventory sensors, they streamline replenishment to optimise stock levels.

Forecasting

Replenishment systems automatically collect sales data and use machine learning to detect demand patterns for every product. Granular forecasts maximise availability while reducing excess inventory.

Flexible Reordering Strategies

The software allows setting custom reorder points and lot sizes tailored to the demand profiles of each item. Strategies like Min/Max and Just in Time are easily implemented.

Continuous Monitoring

Real-time inventory tracking provides complete visibility across the entire catalogue at all times. The system knows precisely when to trigger reorders to align with demand.

Streamlined Procurement

Purchase orders can be automatically generated and sent to suppliers when stock hits reorder points. This eliminates manual order creation work.

Optimised Delivery Logistics

Our replenishment systems can coordinate with your transport providers to help schedule deliveries.

Enhanced Supply Chain Visibility

Stock sales and holding information provide end-to-end transparency across the supply chain. Any bottlenecks or issues can be rapidly identified and addressed.

Evaluating Replenishment Automation Systems

With many solutions now available, choosing the right replenishment platform is critical. Here are the essential capabilities to look for in assessing systems:

Inventory Monitoring – real-time tracking across all stock items in your warehouse and shop with detailed inventory analytics.

Forecasting Accuracy – advanced AI with machine learning and statistical algorithms to maximise the forecast precision.

Order Optimization – balancing target inventory levels, supply constraints, logistics costs and supplier requirements.

Analytics & Reporting – actionable insights into sales, stock levels, supplier performance, waste reduction and other KPIs.

Customer satisfaction – By better inventory best practices, you increase customer service.

The right solution will tailor the capabilities to your business’s specific needs and allow custom configurations.

Our Point of Sale platform provides the most flexibility, scalability and hands-off maintenance.

Realizing the Benefits of Automated Replenishment

Implementing a robust inventory management system unlocks enormous benefits:

Increased Sales

By aligning stock levels with demand and minimizing stockouts, automation enables higher sales and conversions. Customers can find the products they want every time.

Lower Inventory Costs

Carrying excess stock ties up working capital and incurs storage, handling, insurance and spoilage costs. Automating replenishment optimizes inventory investment.

Improved Efficiency

Automation eliminates the hours of manual work traditionally required, allowing staff to focus on more value-added priorities.

Enhanced Forecasting

Automated algorithms crunch enormous amounts of data and detect subtle patterns more accurately than humans. Forecasts improve continuously through learning.

Reduced Waste

Intelligent inventory management avoids overstocking and enables dynamic pricing of perishable goods or expiring products. This cuts waste costs.

Supplier Relations

As a retailer, you are at a disadvantage. Suppliers have far more visibility into true consumer demand and know much more about their product sales in your shop. This allows them to dictate terms around inventory management and delivery schedules to your shop.

Implementing automated replenishment finally gives retailers the data needed to rebalance these partnerships.

With an inventory management system tracking every product in real-time, retailers can gain visibility of their stock that exceeds suppliers' knowledge. You are no longer reliant on the piecemeal date suppliers share.

This allows retailers to optimise orders based on projected demand rather than supplier convenience. Suppliers must become more accommodating to fulfil the order quantities, frequencies and delivery windows specified by the retailer's replenishment algorithms.

Suppliers benefit from retailers sharing their sell-through data. But this is controlled - retailers decide what insights to provide each supplier. This prevents suppliers from misusing the data or acting contrary to the retailer's interests.

Automated replenishment flips the script on the retailer-supplier power dynamic. Retailers can finally dictate the inventory planning relationship rather than relying on supplier practices. This shift rebalances the partnership and benefits the retailer's bottom line.

Start Your Automated Replenishment Journey

If managing inventory still feels like a guessing game rather than a science in your operations, it’s time to explore automated solutions. The technology is more accessible than ever. Replenishment automation unlocks data-driven inventory management, allowing retailers to thrive.

Contact our team today to discuss the best options for your business!