We tend to use a much more formal structure in our point-of-sale system then most.

What I will do here is a few of the terms we use. Note for those that use focus in our system, this is totally automated by our software.

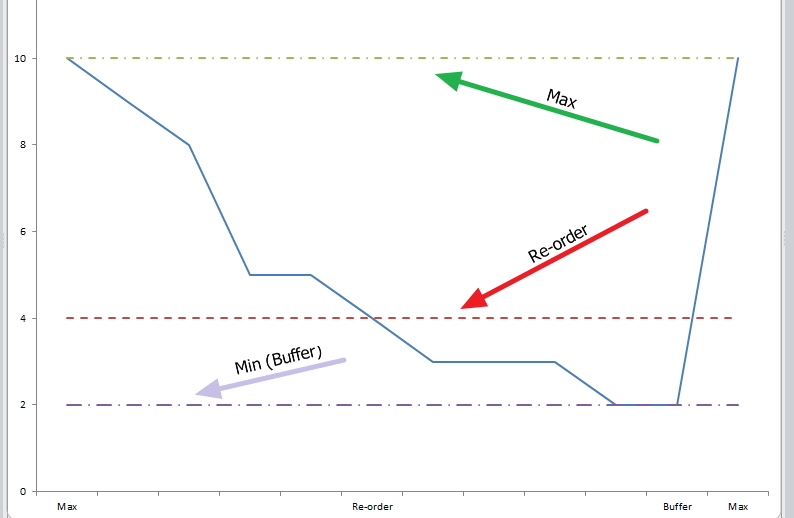

The blue line has the quantity of a particular line in the store.

The Max marked in green is the amount that you feel is the most of that item that you want to hold. So in this case we have stated that we want no more then ten (10).

The reverse of this marked in purple is the minimum, this is often called the buffer stock and is the least number that you want to hold in stock. Commonly these are set to zero which saves time in a manual system but is not right often. In this example, I have made it two (2). Basically, it is determined by how harmful being out of this stock can be.

The re-order point is the trigger for when a new order should be placed ASAP to the supplier. Formally it is determined by the expected sales from the time from when you send an order to a supplier and when these items arrive in your store plus the minimum stock in this case, it's marked in red and is four (4) here.

An interesting observation is that the more often you order the less the maximum, minimum and the re-order points needs to be.