Use your POS Software with Inventory Replenishment

Introduction

Inventory management is an essential part of any business. Businesses need to meet customer demand and avoid stockouts or excessive stockholding. This can only be done by maintaining an optimal stock level that meets customer demand.

Here I will discuss one of the most used methods, inventory replenishment. I will explain how it works and offer suggestions for how to use it to improve your inventory management process.

How is inventory replenishment carried out?

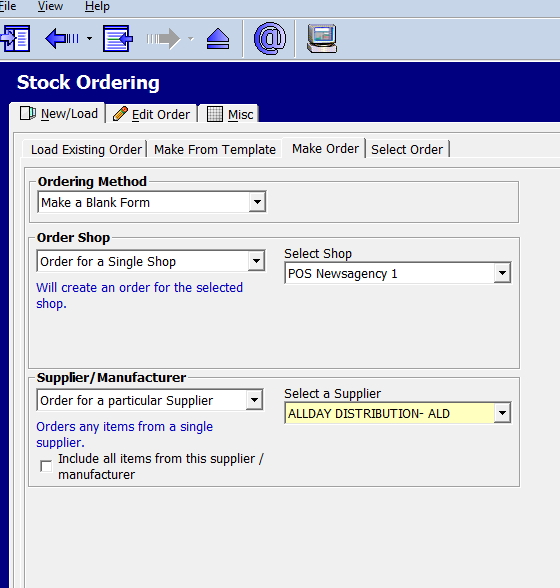

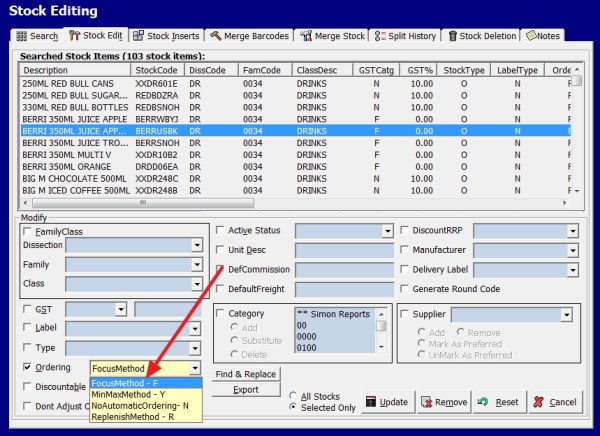

Each item under inventory replenishment has a minimum and maximum desired quantity. These can be either done automatedly or manually set by the user. When the stock-on-hand figure drops below the minimum, the order will be the quantity required to reach the maximum desired figure. Of course, our software has to handle some limitations. For example, the re-order quantity and lead time (the time a supplier takes once they get the order till they deliver the order). If in place, a small business order fee some suppliers charge must be considered too.

If it is done manually, the items are counted. Otherwise, the computer will monitor inventory levels and make a restock alert.

Types of replenishment

Periodic ordering ordering

Done periodically, say when a sales representative comes into the shop or the weekly order is scheduled, the order is done. Your minimum and maximum figure must also consider this cycle. The significant advantage is that you can concentrate on the order as it is done systemically.

The periodic replenishment strategy is ideal for products with a short lead time and high demand.

Re-order Point

The orders are done as the stock falls below the minimum. This involves more work as more orders need to be done, but it reduces your stock holding. In practice, you need a functioning Pont of Sale system to do this, manually, it's too much work.

Demand Replenishment

The process of ordering new stock in response to actual customer demand is known as demand replenishment. Here you use expected demand to calculate the minimums and maximums figures automatically. This is calculated in our system by an AI. It compares your stock-on-hand figures with these demand figures plus adds the uncertainty figures to calculate the order required.

Real-Time Inventory monitoring

To make it work, you must manually count your stock continuously or keep the correct stock levels in your computer system. This ensures that the appropriate inventory quantity is available at the proper time. It is best to have the correct stock figure in your system.

Monitor and change your replenishment strategy.

In practice, it is essential to monitor and modify your replenishment strategy as required regularly. This optimises the process of replenishing your inventory. It could mean switching to a different replenishment method, altering your re-order quantity, or changing your re-order points.

Conclusion

Inventory replenishment is one of the most popular methods of inventory management. It ensures that inventory is available when required without an excessive inventory that becomes obsolete and wastes valuable storage space.

I hope this helps some to understand how it works and how the various replenishment strategies work.